About

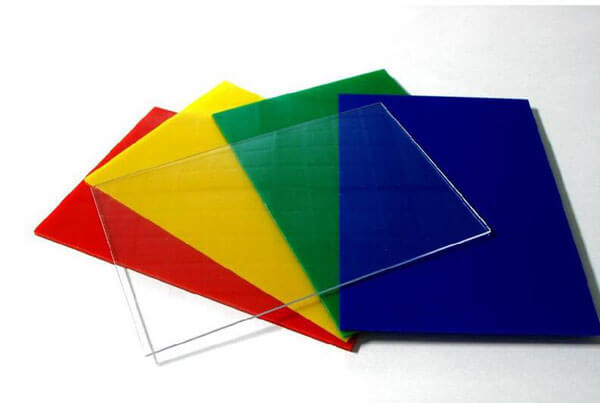

Excel impex is affiliated with Associated group India which is the leading distributor of cast acrylic sheets in India. We particularly deal in A grade material from UB Malaysia & Sumipex Thailand.

Read MoreReach Us

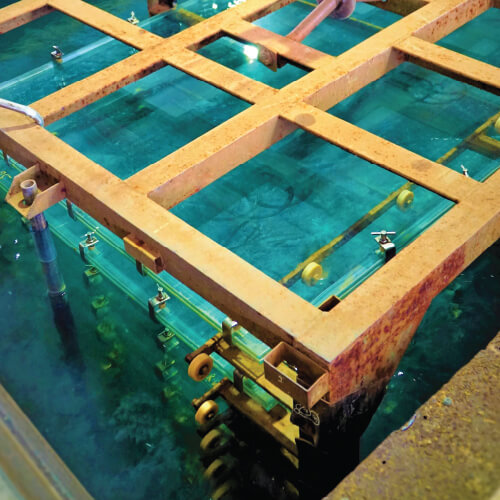

© Copyright 2023 by Excel Implex | Design By CWS