We strive for exellence in all we do through

innovation and continous improvement.

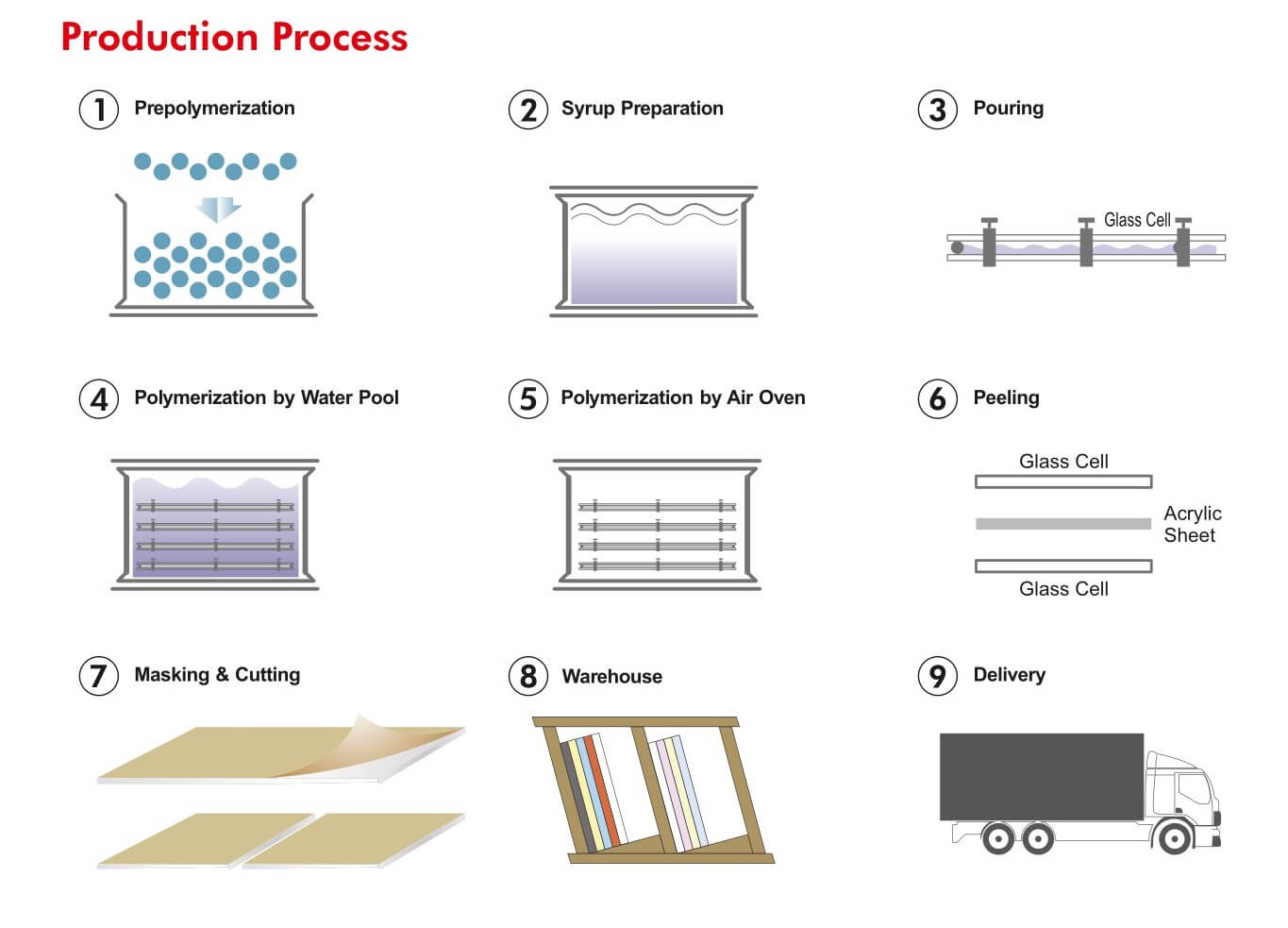

Our acrylic sheets are made from virgin MMA (Methyl Methacrylate Monomer), ensuring the highest

quality product to be produced with excellent clarity, weathering resistance and high strength.

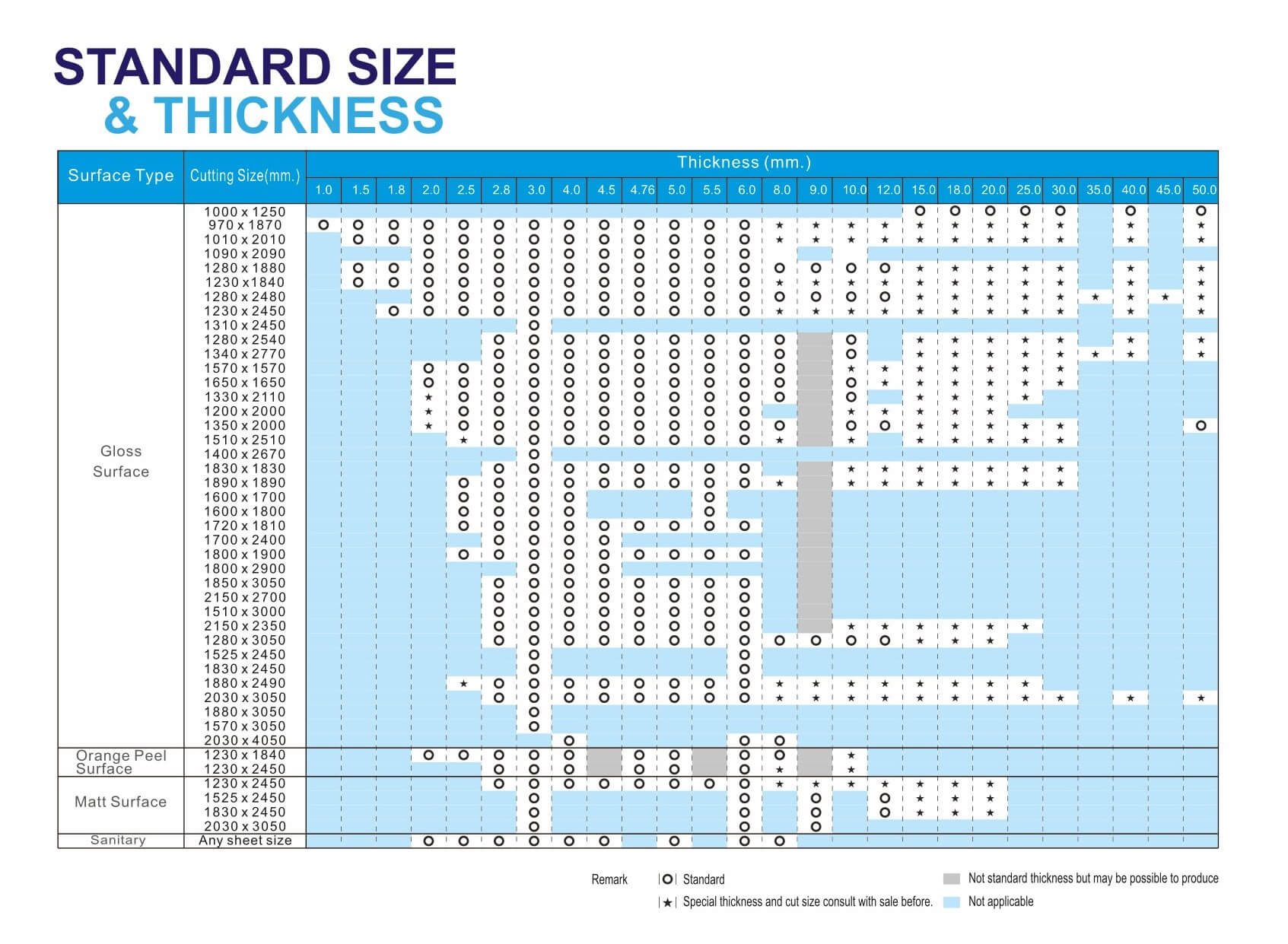

DIMENSIONS

Based on 3 mm (1/8")

Standard Sizes in Width and Length

- 1220 mm x 1830 mm (48" x 72")

- 1220 mm x 2440 mm (48" x 96")

- 1830 mm x 2440 mm (72" x 96")

- 1350 mm x 2000 mm

- 1000 mm x 2000 mm

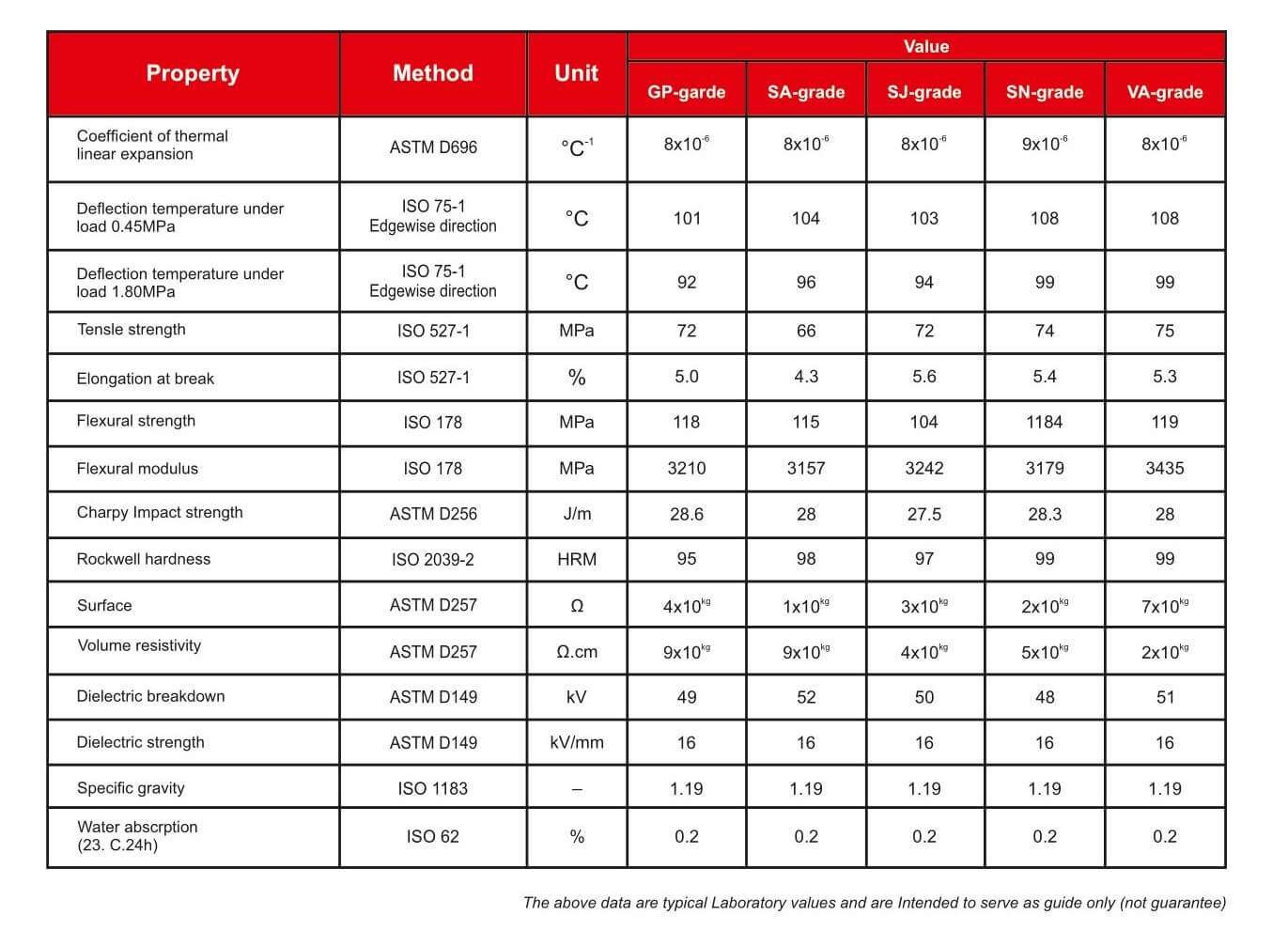

PROPERTIES

(Average value) 3m/m (1/8")

Colourless/Transparent

| Specific Gravity |

1.19 |

| Rock Well Hardness |

M100 |

| Water Absorption (24hrs.) |

0.3% |

| Compressive: Yield |

1260 kg/cm2 |

| Modulus of Elasticity |

3 x 104 kg/cm2 |

| Tensile: Rupture |

560kg/cm2 & up |

| Elongation |

3 - 7% |

| Flexural: Strength |

1050 kg/cm2 |

| Shear Strength |

630 kg/cm2 |

| Impact Strength: (200 gr. steel ball) |

0.4 m |

| Refractive Index |

1.49 |

| Light Transmittance |

91% & up |

| Heat Distortion Temp. |

85oC |

| Coefficient of Thermal Conductivity |

4-6x10-4cal/sec/cm2/oC/cm |

| Coefficient of Thermal Linear Expansion |

7x10-5cm2/cm/oC |

| Max. Recommended Continuous Service Temp. |

85oC |

| Hot Forming Temp. |

140-160oC |

| Specific Heat |

0.35cal/gr.oC |

| Dielectric Strength |

20kv/mm |

| Volume Resistivity |

>1015ohm-cm |

CHEMICAL RESISTANCE

| Sulfuric acid |

30% |

0 |

|

70% X |

| Hydrochloric acid |

10% |

0 |

|

36% X |

| Nitric acid |

10% |

0 |

|

100% X |

| Acetic acid |

10% (of) |

0 |

30% (of) 0 |

98% X |

| Hydrofluoric acid (conc.) |

|

△ |

|

|

| Sodium Hydroxide |

|

0 |

|

|

| Ammonia Water |

10% |

0 |

28% 0 |

|

Note: 0 (Excellent) △ (Good) X (Inferior)

EFFECTS OF SOLVENTS

Unattached at normal temperature:

Hexane, Octane, Formaline 40%, Glycol, Methyl Alcohol, Ethyl Alcohol.

Insoluble but swelled or crazing:

Butyl Alcohol, Isopropyl Alcohol, Carbontetrachloride.

Soluble at normal temperature:

Acetone, Benzene, Toluene, Xylene, Ethylenedichloride, Chloroform, Ethylacetate.

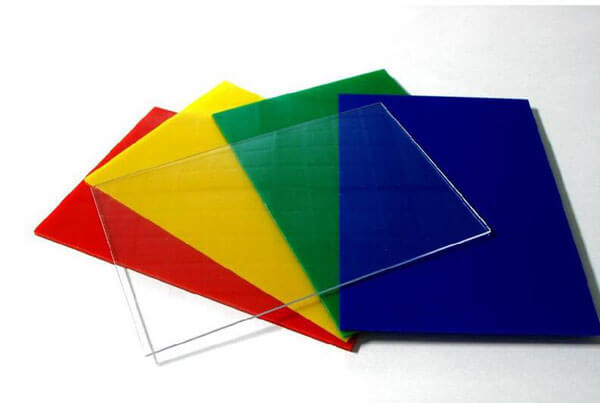

COLOURS

UB Arcylic is transparent, but it can be tinted in various attractive colours to meet any specified requirement. More than 50 colours are currently available, including transparent, translucent, and opaque.

THICKNESS

Standard sheet thickness run from 2 mm to 30 mm.

THICKNESS TOLERANCE

| Thickness (m/m) |

Tolerance(m/m) |

| 2.0 |

± 0.3 |

| 2.3 |

± 0.3 |

| 2.5 |

± 0.3 |

| 2.8 |

± 0.3 |

| 3.0 |

± 0.4 |

| 3.8 |

± 0.4 |

| 4.8 |

± 0.5 |

| 5.0 |

± 0.5 |

| 5.8 |

± 0.6 |

| 6.0 |

± 0.6 |

| 7.8 |

± 0.8 |

| 8.0 |

± 0.8 |

| 9.8 |

± 1.0 |

| 10.0 |

± 1.0 |

| 12.0 |

± 1.0 |

| 15.0 |

± 1.2 |

| 18.0 |

± 1.3 |

| 20.0 |

± 1.5 |

| 25.0 |

± 1.5 |